Common Terms Used In Brick Masonry

There are different terms generally used in the behalf of brick masonry. These need to understand before studying the topic in details. Those are discussing below:

Stretcher: It’s longer face (190 mm x 90 mm) of a brick in the direction of the wall. If the course of bricks contains only stretchers, it’s called a stretcher course (Figure 11. 1).

Header: It’s shorter face (90 mm x 90 mm) of a brick in the direction of the wall. If the course of bricks contains only header, it is known as header course (Figure 1 1.1a).

Bed: The lower portion of a brick (190 mm x 90 mm) when laid flat is known as bed.

Bed joint: The horizontal layer of mortar on brick masonry wall to joint another one layer of bricks is known as bed joint (Figure 11 . 1a).

Arises: The edges of bricks where the surfaces intersect is known as arises (Figure 11.1b).

Lap: In brick wall the horizontal distance between the vertical joints in the successive courses is called lap (Figure 11.1 a).

Perpends: In the alternate courses the imaginary line passing through the vertical joints is known as perpends (Figure 11.1 a).

Quoin: The wall’s face side, a angle at the corner that is 90° normally, but it’s sometimes different is called quoin (Figure 11.1a).

Bat: A bat lengths are half and 3/4th of the full length of a brick and it’s cut across the width is called bat and it’s also called bevelled (Figure 11.2).

Closer: When a brick cuts along it’s length is called closer. There are different types of closer used in brick work whenever necessary.

Queen closer: If a brick cuts into half it’s width is called queen closer (Figure 11.3a).

King closer: In which the corner is cut of a brick so as to get half header and half stretcher adjacent faces is called king closer (Figure 11.3b).

Bevelled closer: This is obtained by cutting a triangular portion of half the width but of full length (Figure 11.3c).

Mitred closer: In which one end is splayed/mitred of a brick. The angle of splay may vary from 40° to 60° (Figure 11.3d).

Toothing: if the wall is extended at a later stage then toothing is given to a wall to ensure proper bond with alternate coarses shown in Figure 11.4. And also toothing is a method of terminating.

Racking back: When a wall is terminated in a stepped manner at the end of the day’s work is known as racking back (Figure 11.5).

Simple Brick Masonry For Houses

Simple brick masonry can be an excellent choice for house construction, providing durability, aesthetic appeal, and a classic look. Here’s a basic plan for a house using brick masonry:

Foundation: Start with a solid foundation made of concrete or stone, depending on local building codes and soil conditions.

Exterior Walls: Use brick masonry for the exterior walls. Typically, a common brick size is 4 inches by 8 inches by 2 1/4 inches. The choice of bond pattern (like stretcher bond or Flemish bond) can add visual interest.

Structural Integrity: Ensure the load-bearing walls are designed and constructed correctly, adhering to structural engineering principles. Consider reinforcements in critical areas for additional strength if needed.

Interior Walls: While the exterior walls are typically made of brick, interior walls might use different materials for cost-effectiveness and flexibility in design. You could use drywall, wood framing, or other suitable materials for interior partitions.

Roofing: Depending on the design, use suitable roofing materials like tiles, shingles, or metal to complement the brick masonry. Properly install the roof to ensure it complements the overall aesthetics of the brickwo

Windows and Doors: Integrate openings for windows and doors within the brick walls, ensuring they are correctly sized and properly framed to maintain structural integrity.

Finishing: Apply mortar between the bricks evenly and neatly, considering the desired finish—smooth, textured, or brushed—to achieve the desired aesthetic appearance.

Maintenance: Brick masonry requires minimal maintenance but periodic checks for mortar integrity and any signs of damage are advisable. Repair any cracks or damages promptly to ensure the longevity of the structure.

Utilities: Plan for electrical wiring, plumbing, and HVAC systems within the interior walls to ensure a functional living space.

Remember, while brick masonry offers durability and aesthetic appeal, it’s essential to consider local building codes, climate conditions, and structural requirements when planning a house construction using brick masonry. Consulting with architects, structural engineers, and experienced contractors is crucial to ensure the success and safety of the construction project.

Requirements Of Good Brick Masonry Works

The following are the requirements below:

✓ The bricks length will be double it’s width and uniform shape and size, plus the thickness of one mortar joint.

✓ Brick across the thickness of wall and lap will be at least 1/4th of a brick along it’s length.

✓ The use of brick bats should be avoided as far as possible.

✓ In alternate courses, the vertical joints will be along the same perpend.

✓ In alternate courses, the centre line of header should coincide with the centre of stretcher in the course below and above it.

✓ Stretchers will be used on the facing only, while hearting should be in headers only.

✓ Every sixth course on both faces of the wall should be a header course.

Bonds In Brick Masonry

There are various types of bonds are generally used in masonry work. These are briefly discussed below:

Stretcher bond:

In figure 11.6 all the bricks are arranged in a stretcher course. However, care is taken to break vertical joints by using 1/2 brick bats. This type of bond is normally used for partition walls that are half-brick thick.

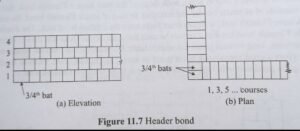

Header bond:

In figure 11.7 shows all the bricks are arranged in the header course, and this type of bond is usually used full for the construction of one-brick thick walls.

English bond:

English bond is used for walls of any thickness, this is a strongest bond in brick masonry work.

Flemish bond:

In this bond alternate courses start with stretcher and header and, each course comprises alternate header and stretcher (Figure 11.9).

If the course starts with a header queen closers are used to break the vertical joints and every header is centrally supposed on the stretcher below it.

There are two types of Flemish bond:

✓ Double Flemish bond

✓ Single Flemish bond

In case of double Flemish bond, both faces of the wall have a Flemish look, that is, each course consists of alternate header and stretcher.

Just in case of single Flemish bond, the outer faces of walls have Flemish look, whereas inner faces have English bond look.

The disadvantages of single Flemish bond are that it can’t be used for walls of thickness but 1+1/2 brick and in some portions, long vertical joints are unavoidable.

Construction of Flemish bond needs great skill. It gives an honest appearance but it’s not as strong as English bond.

Flemish bond could also be wont to get an honest aesthetic look if only pointing is to be used for finished wall.

English cross bond:

In this sort of bond, the alternate stretcher course features a header placed next to the quoin stretcher.

The remainder of the work is analogous thereto in English bond. Figure 11.10 shows a typical English cross bond.

This sort of bond has better aesthetic look and has greater strength than English bond.

Dutch bond:

The alternate courses during this sort of bond are headers and stretches as within the case of English bond.

The difference is within the use of 3/4th bat in stretcher course as quoin.

A header is placed next to the 3/4th bat in every alternate stretcher course as shown in Figure 11.11.

Raking bond:

Very thick walls have fewer stretchers and more headers, which reduces the longitudinal stiffness of the wall.

To beat this defect, raking bonds are used. Raking courses are to be used at certain intervals along the peak of the wall.

The raking bond is of the subsequent two types.

Diagonal bond:

Figure 11.12(a) shows the plan of artificial diagonal raking bond. Internal placing of the bricks is at a particular angle.

The bricks got to be dig triangular shapes to pack small triangular spaces at the ends.

Diagonal bonds are provided at every fifth or seventh course during a wall.

Herring bone bond:

This type of bond is provided at every sixth or eighth course, if the thickness of the wall is quite four bricks.

The bricks are laid at an angle of 450 as shown in Figure 11.12(b).

Zigzag bond:

This is same to herring bone bond except that the bricks are laid during a zigzag manner. this is often commonly used for brick facing (Figure 11.13).

Garden wall bond:

This type of bond is employed for the construction of compound walls, which are usually one-brick thick.

The garden wall bond are often English or Flemish type.

English garden wall bond:

It consists of 1 course of headers after three or five courses of stretchers. to interrupt the vertical joints, a queen closer is placed next to the quoin header.

The center course of the stretcher is started with a header. Figure 11.14 shows an English garden wall bond construction.

Flemish garden wall bond:

Figure 11.15 shows the elevation of a Flemish garden wall bond. during this sort of bond, each course comprises one header after three to 5 stretchers.

It needs 3/4th bat at every alternate course to interrupt vertical joint. A header should be laid centrally over each middle stretcher within the lower course.

Facing bond:

If bricks of various sizes are to be used on facing and backing, facing bond is chosen.In this, a one-header course is provided after several stretcher courses.

The space between the successive header courses is adequate to the smallest amount common multiplier of the thickness of backing and facing bricks.

For instance , if facing bricks are 100 mm thick and backing bricks are 75 mm thick, the header courses are going to be 300 mm apart.

Junctions In Walls

The following types of junctions are built in the construction of brick walls:

(i) T-junction

(ii) Intersection

(iii) Squint junction

✓ T-junctions between English bond walls (Figure 11.16).

✓ T-junction between a Flemish external wall and English internal wall (Figure 11.17).

✓ T-junction in a Flemish bond wall (Figure 11.18).

✓ In Figure 11.19 shows cross-sections are found When two internal walls cross each other. The intersection of walls in an English bond.

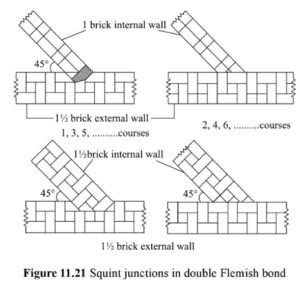

✓ If a wall meets another wall at an angle other than 90°, Squint junctions should be provided. Squint junction in an English bond (Figure 11.20).

✓ Squint junction in a double Flemish bond (Figure 11.21).

Brick Laying

Bricklaying is an art that only a well-trained mason can do satisfactorily. The bricklaying technique involves ensuring a decent bond, also as uniform horizontal and vertical joints.

The procedure of bricklaying involves the subsequent steps:

✓ Spreading mortar on foundation: the highest of the inspiration course is cleaned and made dust free.

About 15 mm thick mortar is spread thereon over a neighborhood to be covered by the corners of the wall.

✓ Laying the primary course of corners:The development of the wall starts at the corners. The corner is marked on the inspiration course (Figure 11.22).

The primary brick is laid at the corner and pressed with hand in order that the thickness of the bed joint is reduced to 10 mm.

Then, the primary closer covered with mortar on the side is pressed against the primary brick so on get a 10-mm joint.

The surplus mortar squeezing out from the edges is cleaned off with a trowel.

The bricks are gently hammered to bring them to the right level. the opposite headers are laid within the same manner because the first closer.

The sting line is checked after laying each brick up the primary course (Figure 11 .23).

✓ Laying the second course within the corner: A 15 mm-thick mortar is cover the primary course.

The top stretcher is laid, pressed and gently hammered to make sure a 10-mm-thick mortar joint.

Then another brick with mortar is placed adjoining the primary and pressed so on get a 10-mm vertical and bed joint.

Mortar oozing out is cleaned off with a trowel. The extent and plumb are checked for the course.

✓ Laying other courses: the opposite courses are then laid at the corners within the same way because the second course.

Similarly, the corner at the opposite end is additionally built.

Plumbing and levelling are checked frequently and adjusted by tapping with trowel.

✓ Construction of in-between portion: Figure 11.24 shows the tactic of stretching a cord along the primary course.

A brick bat is attached at either end of the cord in order that it remains tight. The course is then built.

The cord is shifted to the second course which course is made. The procedure is repeated till the in-between wall is raised to the peak of the corner masonry.

Raising the corners first then building the in-between portion is repeated till the wall is made to the specified height.

Tools For Brick Masonry Works

The following tools are used in brick masonry works:

Trowel: To lift and spread mortar and also cut the bricks trowel is used.

Bolster: Cutting the bricks accurately by using bolster.

Brick hammer: To cutting the Bricks and pushing the bricks in the courses and occasionally.

Spirit level: It’s used for checking the courses built horizontally or not. Simply it’s used for ensuring the level of wall in horizontally.

Plumb rule: For checking the verticality of bricks work.

Mason’s square: Mason’s square is used for checking the right angles simply.

Line and pins: Two pins with 10-m-long cord are used for maintaining the alignment of courses.

Jointer: To pointing the joints between the Bricks by using jointer.

End frames: These are used at the two ends or corners of the brick wall.

They are recommended for brick work to ensure correct alignment of courses, as they are more accurate and can be easily fitted to the corners.

The tools described above are shown in Figure 11.24.

Precaution In Brick Masonry Works

The following points should be observed in the construction of brick masonry works:

✓ In bricks masonry works bricks should be all burnt and exact size and shape as well as a good quality Bricks with uniform colour.

✓ Bricks should be immersed in water at least 2 hours before brick works, that is why, Brick will not absorb water from mortar.

✓ Bricks should be laid with the frog pointing upward.

✓ Construction of brick wall should start from the ends or corner Brick courses should be perfectly horizontal.

✓ Verticality of wall should be ensured by frcqucntly checking with plumb-bob.

✓ Mortar used should be as per specification.

✓ The use of brick bats should be avoided as far as possible.

✓ Walls should be raised uniformly, and in no case should the difference between adjoining walls be more than 1 m.

✓ No wall should be raised by more than 1.5 m in a day.

✓ The face joint should be raked to a depth of 12-20 mm when the mortar is green in order to get proper key for plastering or pointing.

✓ If plastering or pointing is not to be provided, face joints should be stuck flush and finished neatly.

✓ Brick masonry should be left with toothed end whenever the work is stopped.

✓ Holdfasts for doors and windows should be embedded in brick masonry with rich cement mortar or concrete at the time of constructing the wall itself.

✓ Brick masonry works should be cured regularly for two weeks, if cement mortar is used. In case lime mortar is used, curing should be for three weeks.

✓ Only single scaffolding should be used for carrying out brick work at higher level.

Comparison Between Brick Masonry And Stone Masonry

Brick masonry has several advantages over stone masonry:

✓ In brick masonry works no need highly skilled labours, because the shape and size of bricks are uniform.

✓ Bricks can handle easily because bricks are light.

✓ In brick masonry work you can construction thinner walls.

✓ In brick masonry, it is easy to form openings for doors and windows.

✓ Less dead load in brick masonry.

✓ The construction cost will be reduced considerably because in brick masonry work construction joints are thin.

✓ Brick masonry has good fire and weather resistance.

✓ In low-cost and temporary building construction, the brick masonry is more suitable, all types of mortar, even mud mortar can use in brick masonry works.

✓ The transportation cost of the stone masonry is more than the brick masonry, because stones are not easily available around cities where, bricks are available easily available in cities.Bricks are easily available around cities.

There are some disadvantages also with brick masonry:

✓ In brick masonry work strength is low but in stone masonry the strength is high.

✓ Brick masonry is less durable.

✓ The maintenance cost of brick masonry is higher because, in brick works need to plastering, washing and painting of surface.

✓ In Brick masonry has a tendency to absorb moisture.

✓ In stone masonry more architectural effects can be given as compare to that in brick masonry.